BESORA HNOS S.R.L.

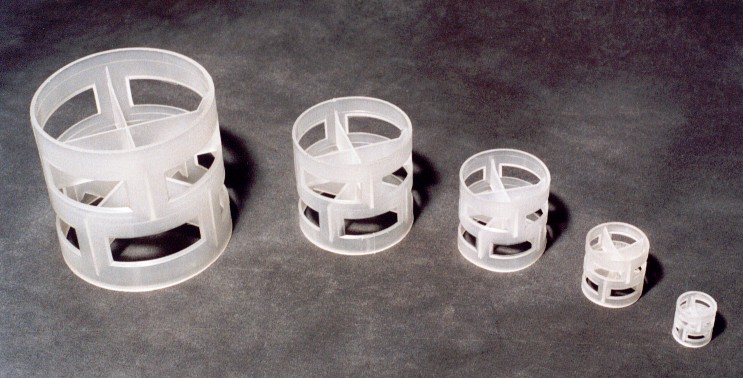

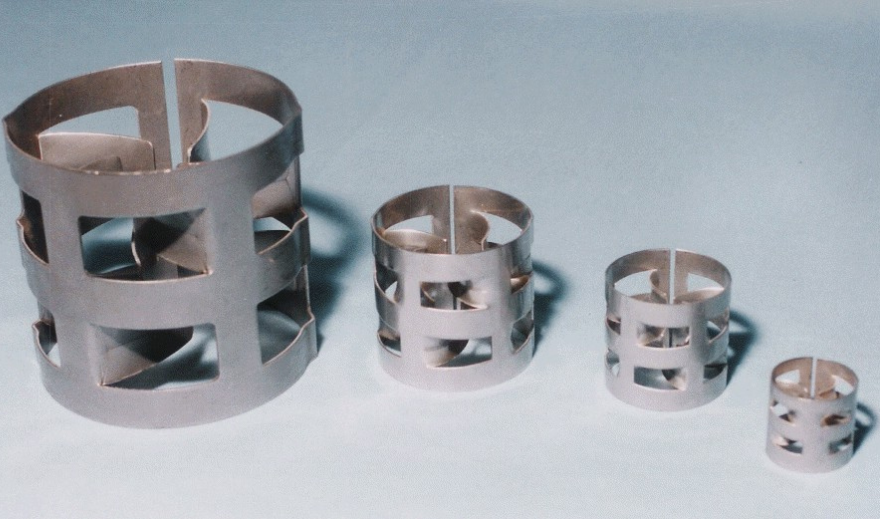

PALL rings

Pall rings are cylinders with slotted walls and inward protrusions with equal diameter and height. The openings and internal surfaces remove the effect of other types of packing that prevent successful performance in columns by providing an excellent contact surface and the redistribution of gases and liquids with all internal and external surfaces.

They provide maximum mass transfer area, while the free space brings about a significant increase in capacity compared to conventional loads. The open-wall design of the ring maintains the initial distribution and allows both the inner and outer areas of the ring to be active in the contact process. The rings maintain a uniform liquid and gas flow pattern. Redistribution requirements are much less demanding than in other types of packing. The redistribution frequency depends on the packing size, the liquid regime, the column diameter, etc., but it is generally not economical that distribution takes place more than every three (3) meters. Pall rings usually have successful results in bed depths of 5 and 6 meters, being the latter a practical maximum limit.

Pall-type packings are used in absorption and extraction columns, cooling towers, CO2 removal systems, SH2, etc., vacuum distillation, gas scrubbing, biological water treatment (trickling beds, denitrification, and the like), deaeration, extractions, etc.

Due to their reduced pressure drop, pall-type packings allow the use of lower power blowers, thus achieving convenient energy savings.

MATERIALS:

Plastics: polypropylene, polypropylene with fiber glass, high-density polyethylene, PVDF (Kynar, Dyneon), etc.

Metal: SAE 1010, AISI 304, 304L, 316, 316L, 430, aluminum, etc.

EASY TO INSTALL: the packing can be quickly and randomly emptied in its tracks into towers, columns, or other equipment. Its design does not require special handling or preparation of the tower since there exists no risk of breaking.